The long-term performance of your solar panels depends on many factors. One of the most devastating causes of PV underperformance is also invisible to the naked eye: microcracks within the silicon cells that make up your solar modules.

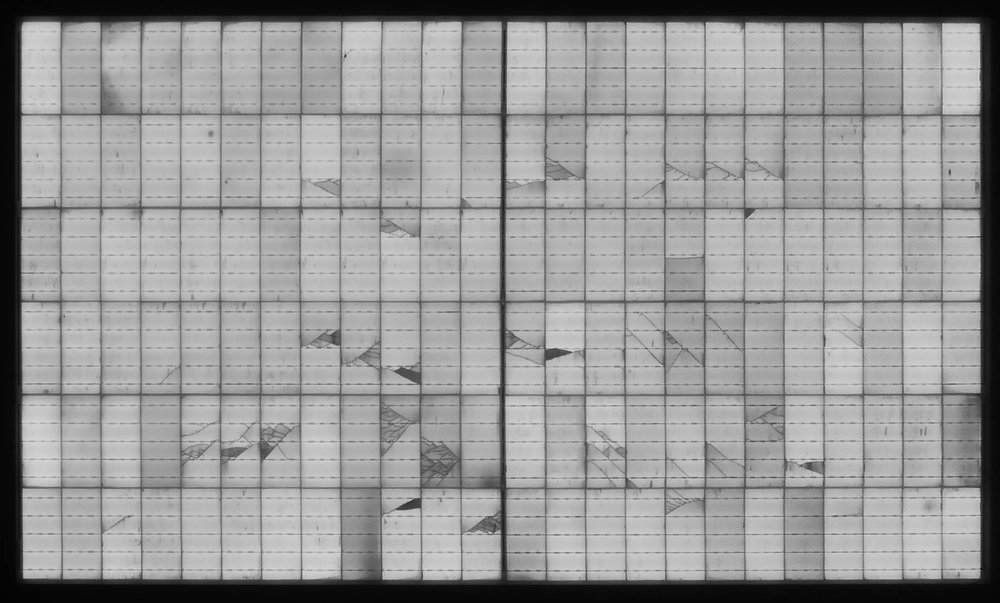

Microcracks are a type of defect that cannot be detected with visual inspection alone. Microcracks are cracks in the silicon wafers formed due to damage at any stage. In many cases these cracks are not immediately apparent through common testing methods like I-V curve tracing and Infrared (IR) scanning but have the potential to develop into a loss of active cell area and reduce the output of the entire string containing a defective module. Over time microcracks can lead to diode activation or hot spots that represent a safety risk.

Quality control during solar panel manufacturing can identify and resolve microcracks before they are shipped, but after the modules leave the production line. Identifying the cause of new damage – either during shipping or from poor installation practices – can be the difference between a successful manufacturer warranty claim, workmanship claim, or absorbing the costs yourself.

Microcracks are present in most solar installations, but catching severe microcracks and removing them early can prevent considerable performance issues and investment losses.

Electroluminescence testing is a non-invasive method used to identify microcracks on site and help in proving the root cause – necessary for warranty disputes. EL testing is performed onsite, and modules do not need to be uninstalled in order for testing to take place. Testing takes place at night so production is not disrupted. PPS takes investor and insurance grade high-resolution images of either a sample of the panels or the entire site to identify damaged, underperforming modules, and the impact points.

PPS has inspected hundreds of thousands of modules through our comprehensive, independent EL inspections, helping clients identify and eliminate underperforming modules, and backing up their warranty claim disputes.

We leverage the EL images we assess during QA work in PV module factories around the globe to quickly and efficiently identify microcracks and other EL anomalies impacting your site performance.

PPS comprehensive, independent EL testing of solar sites provides clients with critical need-to-know information on quality risks in the most efficient and cost-effective manner

Our extensive third-party EL testing experience, including the world’s largest nighttime EL test, has saved clients hundreds of thousands of dollars through successful warranty and workmanship claims, and in early avoidance of severe underperformance.

PPS EL Testing provides:

A good manufacturing QA program ensures that modules are in good condition when they leave the factory. During production, modules undergo EL testing to identify and eliminate microcracks and other defects before they are packed.

Post-shipping inspections can identify poor shipping and handling, can identify damaged modules before they are installed, and can be used as a baseline of incoming quality from the manufacturer.

Post-installation inspections can help identify poor installation practices. Improper installation is one of the leading causes of module damage. A post-installation inspection can also provide a baseline in the event of a severe weather event.

After a storm, module damage is not always visible to the naked eye. Some modules may even continue to produce power. A post-storm EL inspection can reveal the hidden damages from severe weather events like wind and hail.